Green silicon carbide It is a non-metallic mineral product produced by quartz sand (SIO2), petroleum coke (C) and sodium chloride (NAC1) as basic raw materials at high temperatures above 2000 degrees Celsius. Green silicon carbide is suitable for grinding cemented carbide and hard brittle metal and non-metallic materials, such as copper, brass, aluminum and magnesium and other non-ferrous metals and gemstones, optical glass, ceramics and other non-metallic materials.

Green silicon carbide grinding wheel is a porous body made by adding a binder to the abrasive, compacting, drying and roasting. Green silicon carbide grinding wheel code-named GC grinding wheel, suitable for processing cemented carbide, glass, ceramic and non-metallic materials, but also used for semiconductor materials, high temperature silicon carbon rod heating element, far infrared source substrate, etc. Green silicon carbide grinding wheel applications include: grinding materials including cast iron, non-ferrous metals, mild steel, hard steel, 300 (or 400) series stainless steel, tool or high speed steel, malleable cast steel, (Alnico-cobalt) magnet, brass, chrome plate, etc.

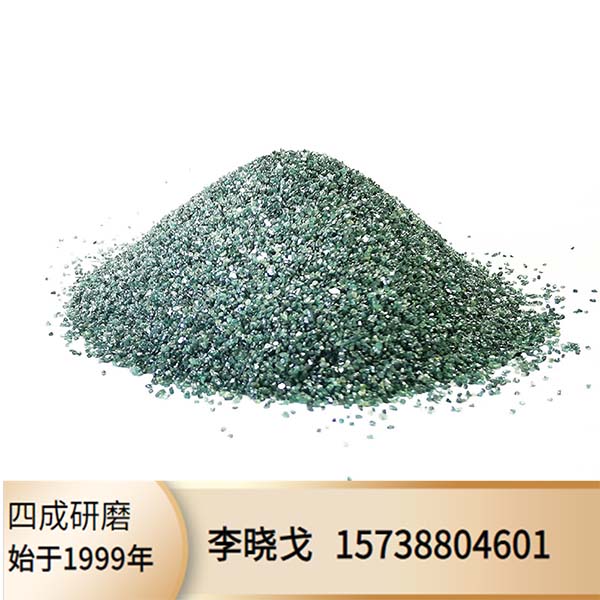

The production method of green silicon carbide is related to Black silicon carbide Basically the same, it has a green translucent crystal. It has the characteristics of high purity, high hardness, small expansion coefficient, brittleness and good thermal conductivity. Abrasives made of it are suitable for processing materials with high hardness and brittleness, such as cemented carbide, glass, agate, etc. Widely used in abrasive, electronic product grinding, refractory materials, special ceramics, foam ceramics, coating plastic addition modification, auto parts, military aviation, steelmaking oxygen absorber, electric heating components and electrical components.

Green silicon carbide mainly has the following application fields: functional ceramics, advanced refractories, abrasives and metallurgical raw materials. Silicon carbide coarse material has been able to supply in large quantities, can not be regarded as a high-tech product, and the application of nano-scale silicon carbide powder with extremely high technology content is unlikely to form economies of scale in a short time.

1. As an abrasive, it can be used to make abrasives, such as grinding wheels, oil stones, grinding heads, sand tiles, etc.

2. As a metallurgical deoxidizer and high-temperature resistant material.

3. High-purity single crystal, which can be used to manufacture semiconductors and silicon carbide fibers.

Main uses: used in semiconductors, lightning rods, circuit components, high temperature applications, ultraviolet detectors, structural materials, astronomy, disc brakes, clutches, diesel particulate filters, filament pyrometers, ceramic films, cutting tools, heating elements, nuclear fuel, jewelry, steel, protective gear, catalyst carriers and other fields.

Abrasives: mainly used for grinding wheels, sandpaper, abrasive belts, oil stones, grinding blocks, grinding heads, grinding pastes and monocrystalline silicon, polysilicon and piezoelectric crystals in the electronics industry in photovoltaic products.

Chemical industry: can be used as a deoxidizer for steelmaking and an improver for cast iron structure, can be used as a raw material for the manufacture of silicon tetrachloride, and is the main raw material for the silicone resin industry.

The above knowledge points about green silicon carbide hope to help you, if you want to know more information, please pay attentionHenan Sicheng Grinding Technology Co., LtdSite:http://sichengml.cn/