The use of multi-wire cutting machine in the cutting industry is more extensive, and the use of green silicon carbide has also increased its popularity, to know that among the many components of multi-wire cutting machine, the use of knives is particularly important, and the main role of green silicon carbide is to increase the sharpness of the knife and increase its use in the cutting process.

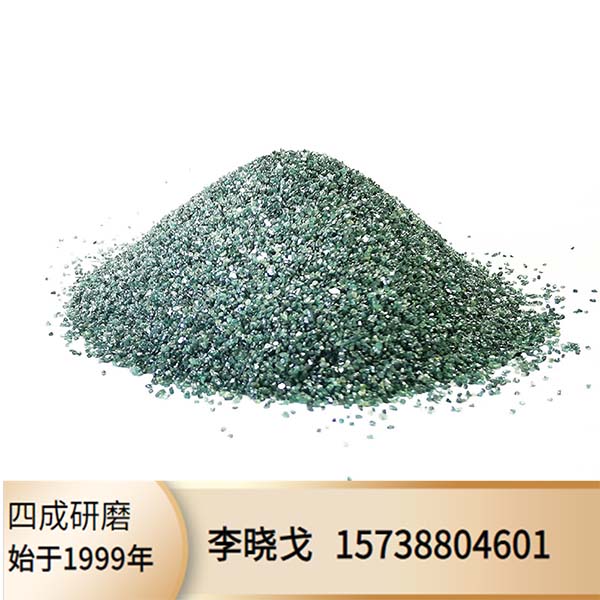

1. Green silicon carbide crystal structure has high hardness, strong cutting ability, good chemical stability and good thermal conductivity. 9.2 hexagonal silicon carbide, microscopic shape of Mohs hardness, Vickers hardness 3000–3300 kg/mm 2, 2670 to 2815 kg/mm, hardness 3300 kg per cubic millimeter Knoop hardness. Higher than corundum abrasive grains and second only to diamond, cubic boron nitride and boron carbide. The density is generally considered to be 3.20 g/mm3, and the bulk density between the specific gravity of 3.20 g/mm3 of 1.2–1.6 g/mm3 of silicon carbide abrasive properties of 3.25.

2. The content of silicon carbide determines the hardness, and the silicon carbide particle size has a great influence on wire cutting, but the important thing is the shape of the silicon carbide particles. Because the cutting line cutting silicon carbide particles are freely changing the cutting efficiency and cutting quality shape has an important influence on the state. Green silicon carbide is a kind of high-quality petroleum coke and silica as the main raw materials, added salt as additives, by high-temperature resistance furnace melting. Its hardness of corundum and diamond, than the mechanical strength of corundum.

3. Because of the development of the photovoltaic industry, the demand for green silicon carbide for silicon wafer wire cutting is increasing, and green silicon carbide for silicon wafer wire cutting is an indispensable special material in the production of silicon wafers for solar cells. Because of its own characteristics, silicon carbide powder is more suitable for cutting cutting cutting links of photovoltaic and semiconductor wafers. The grain shape and size of the product are the key to the smoothness and cutting ability of the silicon wafer surface. For example: the particle type and particle size of silicon carbide powder, the viscosity of mortar, the flow rate of mortar, etc. The cutting essence of the silicon wafer is that the particles are cutting, the grain type is regular, the surface finish of the cut silicon wafer will be very good, the particle size distribution is narrow and uniform, and the cutting ability of the silicon wafer will be improved. In the upstream silicon wafer multi-wire cutting technology of the photovoltaic industry, the multi-wire cutting technology mainly uses green silicon carbide as the cutting edge and supplemented by other reagents for cutting, in this technology, the quality of green silicon carbide directly determines the efficiency of slicing. Therefore, green silicon carbide is an indispensable consumable material in the cutting process, also known as the knife in the hands of photovoltaic companies. Therefore, it occupies a pivotal position in the slicing industry.

Why green silicon carbide will become an abrasive used in multi-wire cutting machines, and its own use effect is inseparable, to have a better and sharper knife to use it is right.