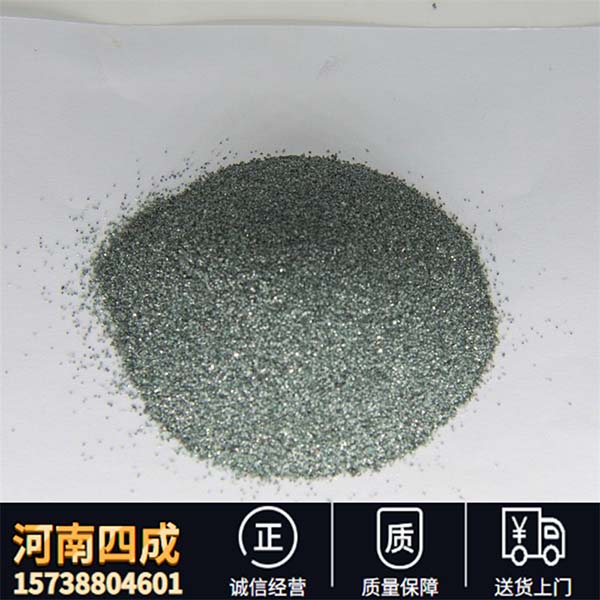

Green silicon carbide powder is based on quartz sand. Petroleum coke is the main raw material, which is smelted at high temperature in a resistance furnace. Its hardness is between corundum and diamond, its mechanical strength is higher than that of corundum, and it is brittle and sharp. It has certain electrical and thermal conductivity. Green silicon carbide powder has a green appearance, crystal structure, high hardness, strong cutting ability, stable chemical properties and good thermal conductivity.

Green silicon carbide powder has good self-sharpening and excellent grinding and polishing properties. In recent years, with the development of the world’s semiconductor industry, the main application of green silicon carbide powder is in the multi-wire cutting and grinding of single crystal silicon, polycrystalline silicon, piezoelectric crystal and other electronic engineering. It is used for wire cutting of single-product silicon, polysilicon, potassium arsenide, and quartz crystals of 3-12 inches. It is an engineering processing material for solar photovoltaic industry, semiconductor industry and piezoelectric crystal industry.

Green silicon carbide powder is a high-purity silicon carbide grinding powder with excellent chemical stability at room temperature. At present, silicon carbide powder is mainly 1200# and 1500#. Since silicon carbide micropowder is mainly used in the abrasive industry. Therefore, there are special requirements for the classification of micropowder, and no large particles can appear in the micropowder. Therefore, in order to meet the requirements of international and domestic products, JZF grading equipment is used for high-precision classification in general production.

The so-called quality of green silicon carbide powder is based on the demand. 1200 and 1500 are mesh numbers, and the larger the mesh number, the smaller the particles. If 1500 silicon carbide is required, the central value should be 8.5 microns. The quality depends on whether the particle size in this range is relatively concentrated.