Silicon carbide product introduction:

Black silicon carbide is made of quartz sand, petroleum coke (or coal coke), wood chips and other raw materials in a resistance furnace by high temperature smelting, black opaque body, hexagonal crystal, Mohs hardness of 9.15.

Silicon carbide has a large hardness, excellent thermal conductivity, is a kind of semiconductor, and can resist oxidation at high temperatures. It is mainly used for grinding wheels, artificial stone, sandstone, sandpaper, abrasive belts, oil stones, grinding blocks, grinding heads, grinding pastes and monocrystalline silicon, polysilicon and piezoelectric crystals in the electronics industry in photovoltaic products.

Black silicon carbide physical indicators:

| Black silicon carbide | |

| Model | 8–220#,240#–8000#,F230-F2000. |

| Main ingredients | SiC |

| color | black |

| Mohs hardness | 9.15-9.50 |

| True density | 3.2-3.45g/cm3 |

| melting point | 2250℃ |

| Maximum operating temperature | 1900℃ |

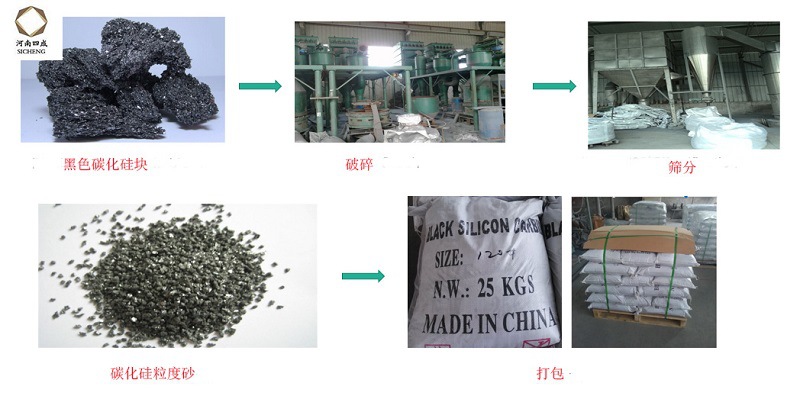

Black silicon carbide particle size sand production process:

Chemical indicators of black silicon carbide particle size sand:

|

Black silicon carbide particle size sand is used for abrasive, sandblasting, grinding, polishing |

|||

|

attribute specification |

8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220#. |

||

|

Guaranteed value |

Standard value |

||

|

attribute rules |

SIC |

98.0 min |

98.5 |

|

F.C |

0.2 max |

0.1 |

|

|

Fe2O3 |

0.2 max |

0.15 |

|

|

H2O |

1.0max |

0.30 |

|

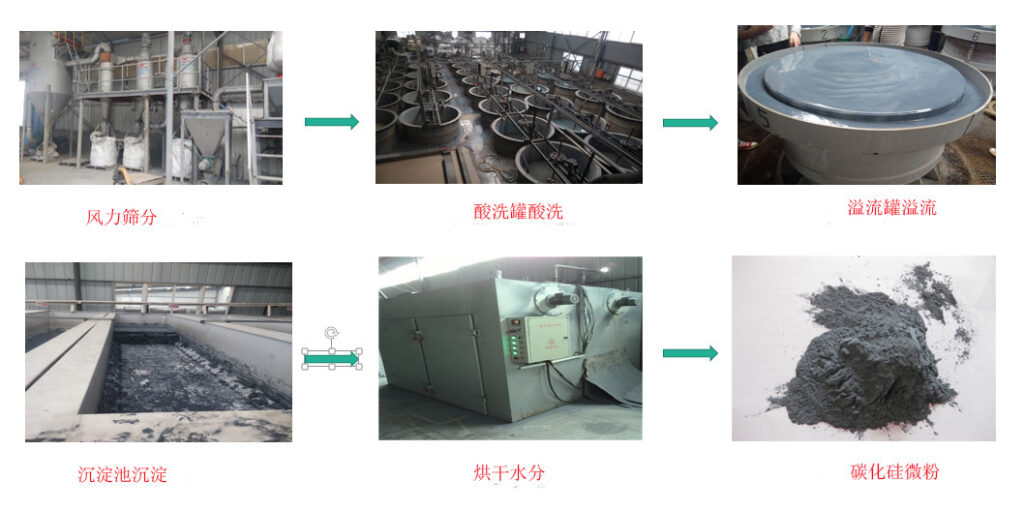

Black silicon carbide powder production process:

Black silicon carbide powder chemical index:

| Black silicon carbide powder is used for abrasive, grinding, polishing | ||||

|

attribute specification |

FEPA | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | ||

| HE | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# | |||

| Guaranteed value | Standard value | |||

|

chemical composition |

SIC | 97.0 min | 97.5 | |

| F.C | 0.3max | 0.2 | ||

| Fe2O3 | 0.2 max | 0.15 | ||

| H2O | 1.0max | 0.3 | ||

The main uses of black silicon carbide:

1. Polishing of machine parts

2. Polishing of metal products

3. Polishing of precision instruments

4. Polishing of glass lenses, prisms, and flat crystal products

5. Micronized powder is suitable for refractory materials, ceramics, special coatings and other industries.

Henan Sicheng Grinding Technology Co., Ltd. is a professional silicon carbide manufacturer, the factory was established in 1999, passed ISO 9001Product quality certification.