The three elements of high-grade abrasives

1. High cleanliness

Put the abrasive into a glass and stir with water, the aqueous solution is clear and transparent, and a small amount of suspended solids.

Second, high bulk density, low particle roundness value

The grinding efficiency is high and the surface finish of the workpiece is good.

3. High purity:

|

Silicon carbide content |

Ferric oxide |

Free carbon |

|

|

P12-220 |

≥99.50 |

≤0.10 |

≤0.15 |

|

P240-400 |

≥99.00 |

||

|

P500-1200 |

≥98.50 |

||

|

P1500-3000 |

≥98.00 |

≤0.20 |

Detailed use

2. Used for wear-resistant layer surface, such as wear-resistant layer on skateboard surface, wear-resistant runway.

3. Used for sandblasting metal, tank body, gear surface, sandblasting effect is excellent

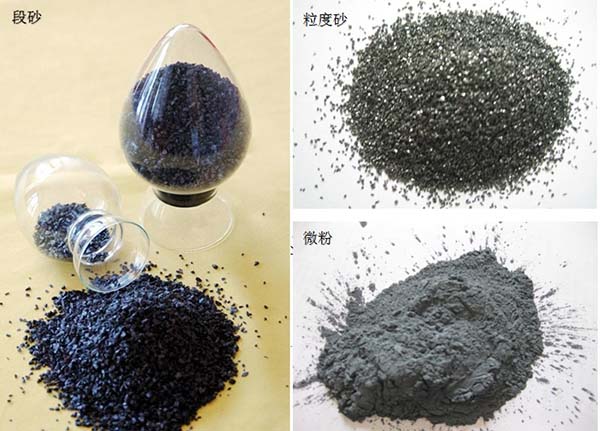

Product Variety

If necessary, please feel free to contact Manager Xu, 13700874751, and serve you wholeheartedly.

Production process

Exquisite packaging

Our advantage

1. First-class equipment, fine production process monitoring, from raw materials, to semi-finished products, to finished products, each link is regularly sampled and tested to ensure the first-class quality of products.

2. Pickling process, all black silicon carbide products in our factory are pickled, cleaner.

3. Packing: We use automatic weighing equipment for bagging to ensure that each bag is sufficient.

4. We have a professional and fast logistics department to ensure that the goods are delivered to your place of use in time.