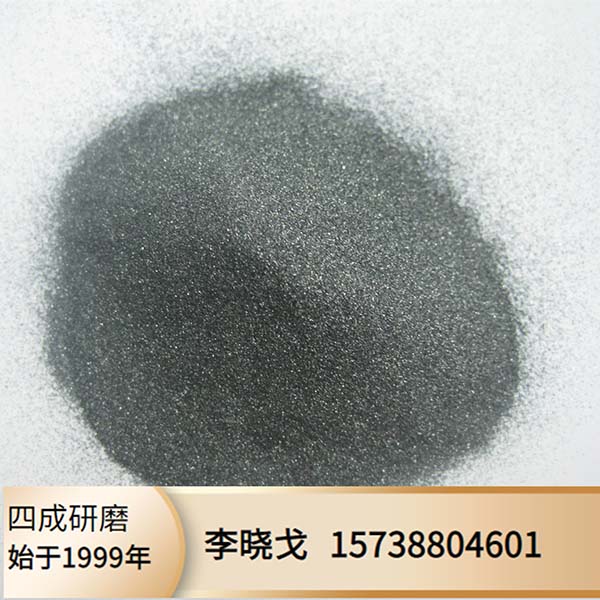

The silicon carbide we have seen is generally black, so it is called black silicon carbide, so why is it black? In fact, there is not only the color of black but also green, the color of black may be produced because it will inevitably occur in the production process, and then black silicon carbide manufacturers will solve the confusion for everyone.

Black silicon carbide is made of quartz sand, petroleum coke and good quality silica as the main raw materials, and is smelted at high temperature by resistance furnace. The raw materials used in the manufacture of green silicon carbide, such as black silicon carbide, are roughly the same, and industrial salt is added as a reactant and accelerator in the resistance furnace reaction. Generally, the silicon carbide we see has two colors, one black, one green (quartz sand, petroleum coke, return material, wood chips, etc. will be used in the processing process), and the content of different colors will have certain differences in use. But why does industrial silicon carbide appear black or green?

There is an idea that the reason why silicon carbide appears black is because the crystals are wrapped in fine carbon particles. When salt is not added, due to the rapid evaporation rate of silica, the carbonaceous material does not have time to react with it, resulting in a part of the silica vapor escape, while the carbonaceous material is not complete, leaving fine particles in the silicon carbide crystals that have been generated. In the production of green silicon carbide, we often say that one more element than black silicon carbide smelting is salt, because salt can promote the green color of silicon carbide products.

However, after a large number of experiments for a long time, some manufacturers have found that in the process of smelting green silicon carbide, the impurities in the raw materials (aluminum, calcium, magnesium, boron, etc.) are more than pure green silicon carbide. Conversely, if the purity of the raw material is too high, fresh green silicon carbide can be smelted without adding salt. Sometimes there are some side effects in the process of smelting green silicon carbide into table salt, which is to increase the leakage of the charge and the furnace body, and aggravate the corrosion of equipment and plants. Therefore, in the process of smelting silicon carbide, more attention needs to be paid to the use of salt.