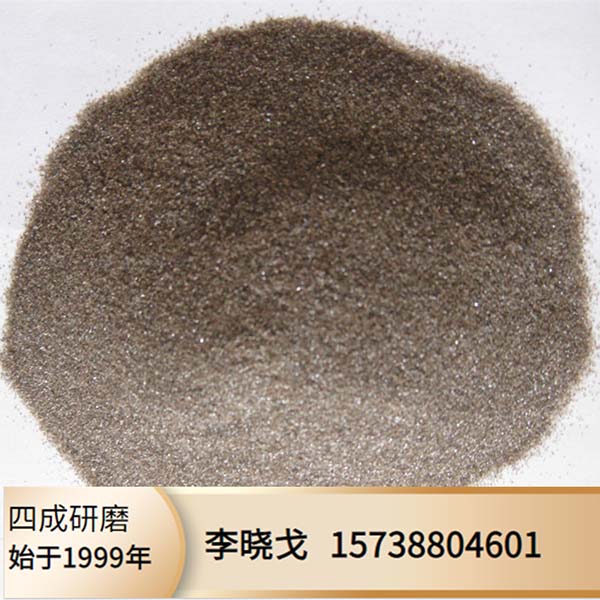

Nature and usefulness. Corundum is a pure crystalline alumina (AI2O3), due to often containing a certain mixture and a variety of divergent colors, such as chromium containing red, chin containing blue, iron containing brown, manganese containing rose, corundum hardness in the natural mineral second only to diamond, primary as a high-grade grinding material, can be made into corundum grinding wheel, grinding disc, grinding paper and grinding powder, etc., mainly used for the polishing and processing of metal finished products, can also be used as the instrument fast rotation department bearing, Corundum powder can also polish the optical glass of tight instruments, while transparent and brightly colored corundum can be used as a gemstone.